About - Technology Application Areas

Application Areas

Revolutionizing Implants / Onplants with Bio-Active Glass Coatings

Metallic orthopedic implants have been successfully used for decades but they have limited success due to the limited osseointegration and the fact that their properties do not match those of bone.

Covalent Coating Technology (CCT) has worked with MoSci Corporation to develop a novel coating processes that envelops titanium with a Bio-Active Glass that will revolutionize the implant market by creating a more bio-friendly surface. Significant innovation on this patent pending process, has enabled CCT to prove it’s capability to coat various geometries and sizes of medical grade titanium alloy.

Implant / Onplant and the Coating Advantage

Coating nonferrous metals such as titanium alloys with a tenacious glass coating is known to have limits exhibiting a variety of defects that could lead to faulty surfaces. Successfully creating that coating allows the possibility of:

Bio-Friendly Coating

- Implants, Onplants and other components come in various shapes and service requirements. Each requires that the body not reject or become infected due to the device. Homogeneity of the metal and any coating applied is required to assure there is no gap for foreign substance; bacteria, viruses, food or the like to lodge and become infected.

- Implants, onplants and other medical device components have various requirements and form factors. In general, that they must have bio-friendly surfaces. Both a bio-friendly chemistry and shape that does not harbor foreign substances such as bacteria, viruses, or particulates such as food.

Covalent Bond

- A coating alters the surface of a device and allows the body to interact with the product differently. The coating can improve the potential for tissue growth, can be a delivery mechanism for a medication amongst other possibilities. Delamination is a very real problem with coatings that is minimized by the type of bond between the base device and the coating.

- One approach to adhering the coating to the metal substrate is by chemically bonding the material to the substrate versus mechanically bonding to the substrate. This, CCT does by preparing both substrate and bio-glass to create a diffusely defined interface that is stronger than previous interfaces attempted by other glass to metal systems. Different from a plasma sprayed, PVD or CVD coating, this chemically bonded coat is an extremely strong adherent to the substrate creating a tenacity that is hard to recreate using other methods.

Integrated Custom Material Coating Solutions

Patent Pending process for Bio-Active Glass applications.

Advanced Engineering Services for various complex material needs.

Full System Application Development.

- Develop coating material and systems to meet our customers needs

- Regulatory proficiency to aid product qualifications

- If you have a designed coating material, we can create the coating process

Portfolio of Coatings: specialize in advanced coating technologies to provide whole solutions.

System Development: each application requires special materials. The coatings must be tailored to base material and environmental conditions.

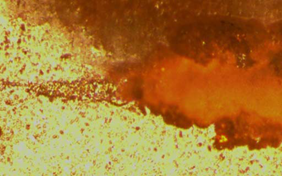

Bio-Active Glass Coated Titanium Sample